Welding

Welding equipment is an integral part of almost all industries. Welding equipment provides fast and reliable fusion of various metal parts. It is widely used in manufacturing, construction, metallurgy, making metal structures, automotive, etc.

At the moment, about 150 types of welding processes are used. All welding processes can be classified by physical, technical and technological features.

The main physical attribute of welding is the form and type of energy used to produce a welded joint:

- Thermal class: welding carried out by fusion using thermal energy – gas, arc, electron beam, laser and others.

- Thermomechanical class: welding carried out with the use of heat energy and pressure – contact, diffusion, gas pressure, arc pressure and others.

- Mechanical class: welding carried out using mechanical energy – cold, friction, ultrasonic and others.

The technical criteria include: the method of protecting the metal in the welding zone, the continuity of the process, the degree of its mechanization.

Classification by technological criteria is established for each type of welding separately (by type of electrode, type of welding current, etc.).

Power semiconductor devices are an integral part of all welding machines. The Proton-Electrotex company produces power semiconductors for welding machines and robots.

Welding diodes produced by Proton-Electrotex are used in resistance welding machines. Operation of diodes in welding machines is characterized by short-term cycles of current pulses leading to the heating of the semiconductor structure followed by its cooling. As a result, the devices are subjected to repeating cyclic thermomechanical stress. This dictates stringent requirements to the static and dynamic properties of devices.

IGBT modules manufactured by Proton-Electrotex are widely used in welding inverters. This type of welding implies high frequencies. The required welding current is achieved by converting high-frequency currents.

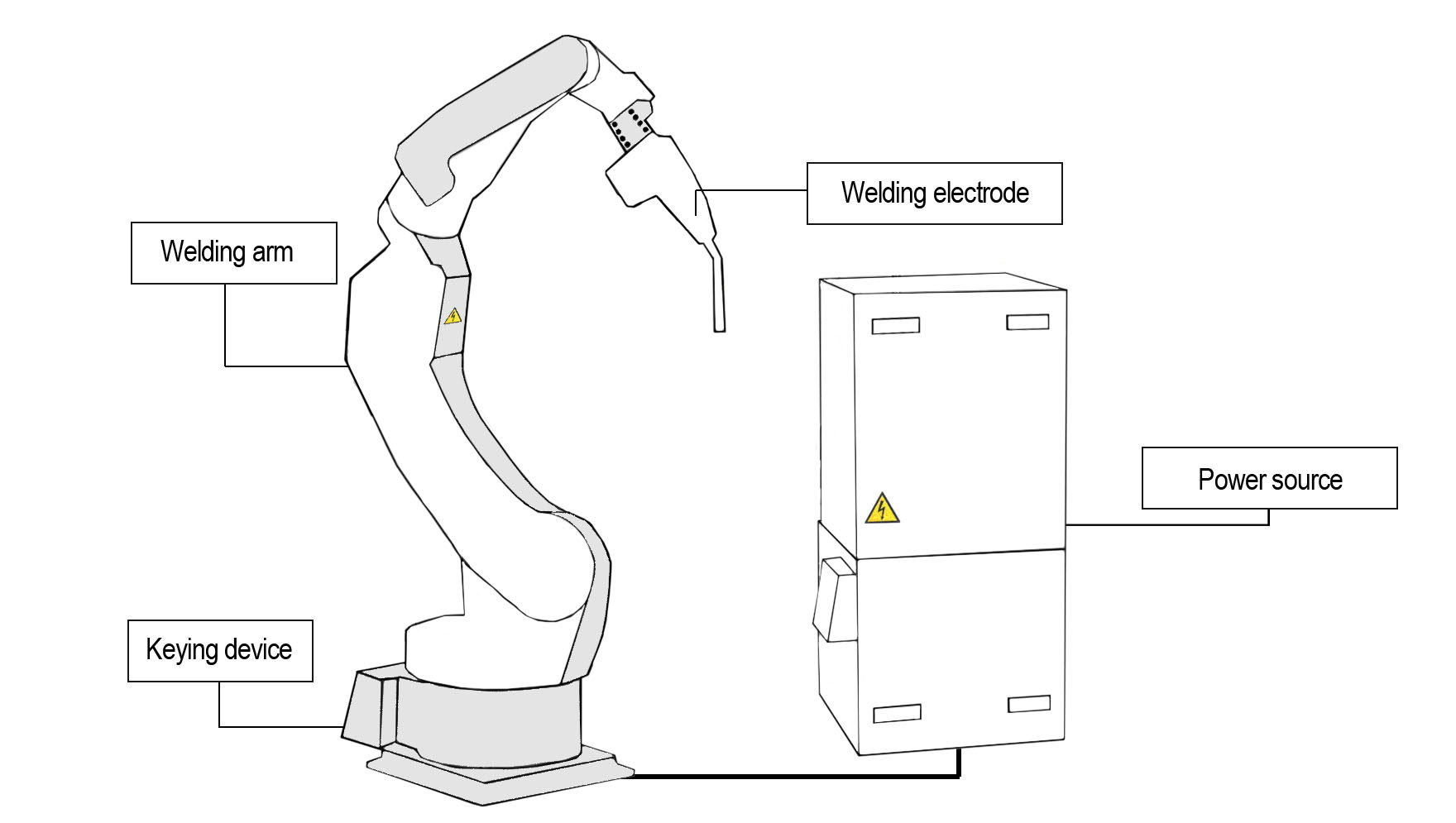

It is also worth to mention the booming sector of welding robots. These solutions, as a rule, are commonly used in heavy industry. The welded products are moved on a conveyor in front of the manipulator during the manufacturing process, and a precisely configured robot performs the welding with a high degree of accuracy. The speed and continuity of work allow to perform a large number of operations per minute, while the interface allows the operator to calibrate welds, control the movement of the axes and the torch according to a given virtual model.

Robots are used for welding small, compact parts and large massive workpieces of any shape made of metal, alloys, plastic and other materials.

Power semiconductors manufactured by Proton-Electrotex meet the highest requirements for durability, quality and precision. This is especially important in the operating environment of welding equipment.

Proton-Electrotex has created a specialized laboratory of operational reliability that is mainly used to conduct classification and periodic tests, tests for reliability and to determine the ultimate useful life of the devices, allowing the company to produce high quality power semiconductor devices.

All manufacturing processes at Proton-Electrotex are organized in strict accordance with the requirements of the quality management (ISO 9001) and environmental management (ISO 14001).

Power semiconductors come in a variety of designs. Proton-Electrotex produces multiple types of semiconductors for welding equipment in stud, disc and module designs.

Besides, Proton-Electrotex offers wide customization opportunities, taking into account individual customer requirements for technical parameters, connections and appearance of devices. Please contact the sales department for advice or leave your request online.

Applications

-

Power Semiconductors fo Welding Equipment

-

Welding inverters

Welding inverters -

Rectifiers for resistive welding units

Rectifiers for resistive welding units

-

-

Strengths of devices made by Proton-Electrotex

-

In-house development

In-house development -

Complete production cycle

Complete production cycle -

Close cooperation with suppliers

Close cooperation with suppliers -

Ability to make custom products

Ability to make custom products

-