Metalworking Services

JSC Proton-Electrotex offers a range of metalworking services for corporations in various industries. We perform metal processing of any complexity using modern equipment and technologies, ensuring high quality of products.

The mechanical production of JSC Proton-Electrotex has been operating since 1997. Our team have the experience and qualifications to provide a range of services and manufacture unique parts according to individual customer requirements.

We offer the following services:

|

Injection molding tooling for thermoplastic injection molding machines. Casting of parts on customer's tooling.Full-cycle production of molds and tooling for injection molding - from design and blank production to final processing. Development and manufacturing are based on customers technical requirements. |

|

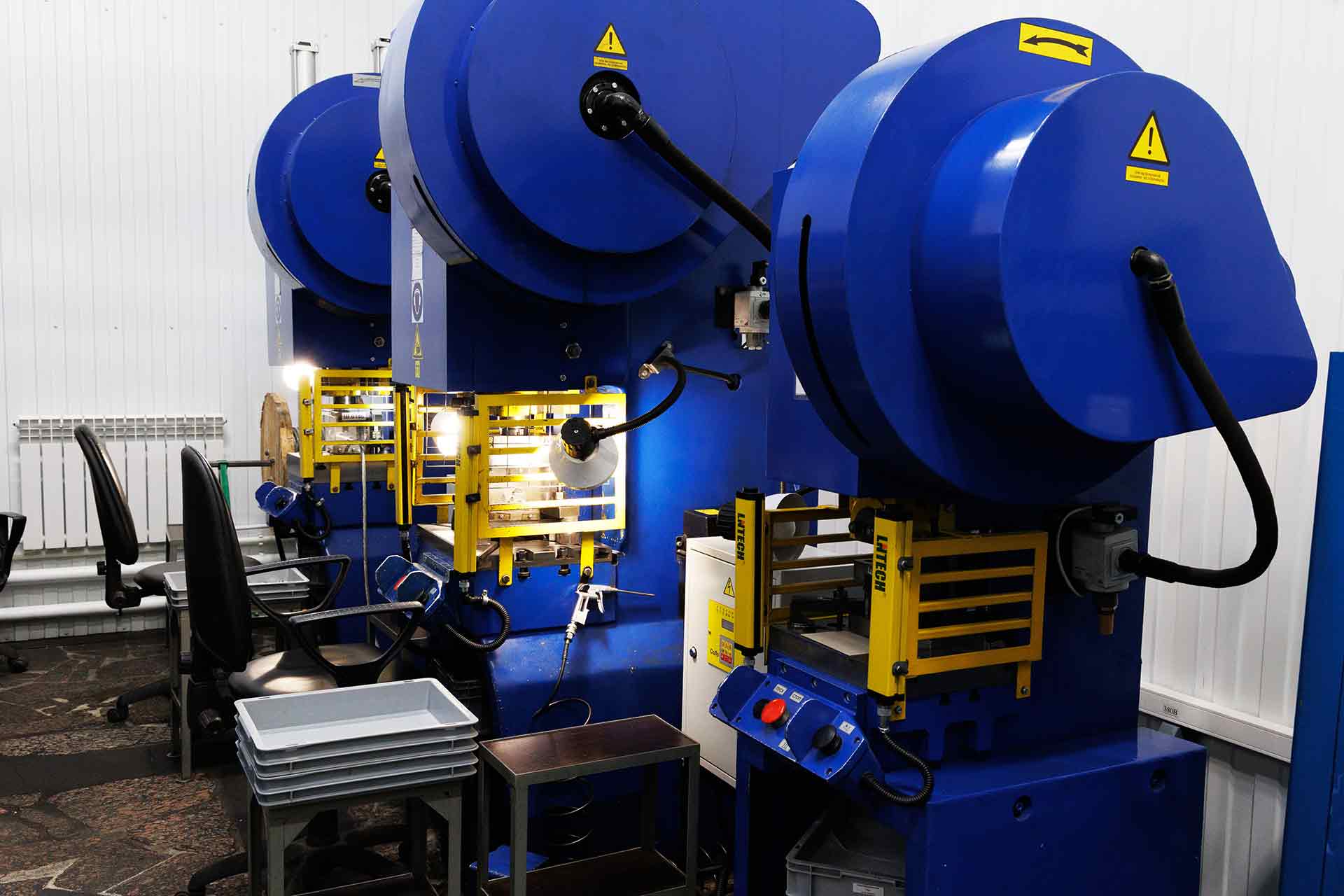

Stamping tooling according to customer specifications. Stamping of parts on customer's toolingA full cycle of custom-made stamping equipment production for use on the customer's existing equipment. Stamping equipment is manufactured using modern design programs and methods, which allows for the manufacture of stamps and molds of various sizes and levels of complexity. |

|

Manufacturing of parts with varying complexityManufacturing of parts using the capabilities of turning, milling, stamping, heat treatment, annealing of non-ferrous metals, plastic casting. Manufacturing are based on customers technical requirements. |

|

|

Heat treatment and annealing of partsHeat treatment of parts is carried out in chamber furnaces. Annealing of parts is carried out in furnaces using a protective gas environment. |

|

Product designA range of services for the development and design of products, including the development of technical drawings, 3D models, complete technical documentation package. All design documentation is prepared in compliance with regulatory requirements while accommodating customers needs. |

The technological capabilities of JSC Proton-Electrotex allow us to carry out work on technical cleaning of components and surface preparation for electroplating. Work can be carried out with ferrous and non-ferrous metals, polymers, textolites, and other materials.

All production processes are organized according to industry norms and standards . Our mandatory three-stage quality control system ensures superior product quality.

Advantages of working with Proton-Electrotex

-

-

Flexible working terms

Flexible working terms -

Three-stage quality control

Three-stage quality control -

Modern equipment

Modern equipment -

Experience since 1997

Experience since 1997

-

Cooperating with JSC Proton-Electrotex, you can reduce production lead times, optimize labor costs, and enhance product durability and quality.

|

|

|

|

|

|

Contact us to discuss your order or get advice on any issue of interest, we will offer the best solution for your production.

We guarantee the accuracy and quality of every detail!