Diodes

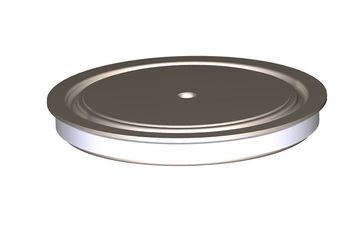

Diode D053-7100

Diodes

| VRRM [V min]: | 200 |

| VRRM [V max]: | 400 |

| IFAV [A]: | 7100 |

| Tс: | 90 |

| VFM (Tc=25°С) [V]: | 1.05 |

| IFM (Tc=25°С) [A]: | 5000 |

| VF(TO)/Tjmax [V]: | 0.750 |

| rT/Tjmax [mΩ]: | 0.029 |

| Tjmax [°С]: | 170 |

| Rthjc [°С/W]: | 0.0090 |

| Package: | D.Q1 |

| Design: | disc |

| Type: | welding |

- Documents and certificates

- Datasheet Diode D053-7100

- Application Note Open PDF

- STEP model of the device Diode D053-7100

- Description

D053-7100 is a welding diode in disc design. It has a repetitive peak reverse voltage VRRM of 200-400 V and low static losses. Mean forward current IFAV equals 7402 A. Industry standard design enables easy installation into existing equipment. Maximal junction temperature Tjmax is 150 °C. Diameter of the contact surface is 44.4 mm.

"D0" series of welding diodes by Proton-Electrotex has the following features:

∙ ability to conduct high mean forward current, allowing to reduce the amount of parallel devices

∙ high resistance to electric and thermal cycling ensures a long service life;

∙ minimal static losses;

∙ high maximal junction temperature (Tjmax) allows these diodes to conduct higher current with the same cooling system;

∙ possibility of double-sided cooling;

∙ optimized for high current rectifiers;

∙ very low thermal resistance;

∙ designed for medium-frequency welding equipment.

At the customer's request Proton-Electrotex is able to select the optimal power diode for given operation modes. It is also possible to ship ready-to-use power semiconductors in assembly with heatsinks.To buy the D053-7100 diode, request a quotation or a technical advice, please contact the sales department by phone +7 4862 440456 or email marketing@proton-electrotex.com.

- Applications

Welding diodes are mostly used in contact welding machines. Operation in welding machines is characterized by short impulses of current causing the semiconductor structure to heat and then cool down, as a result of limitations of welding machine duty cycle (modes "operation - cooling"). As a result, the semiconductor is exposed to frequent cyclical thermal and mechanical stress. All this imposes harsh requirements to static and dynamic properties of the devices.